WELCOME

Situated in the French region Auvergne – Rhône Alpes, Manuthiers specializes since 1958 in serial production of injected plastic parts and the manufacturing of injection moulds.

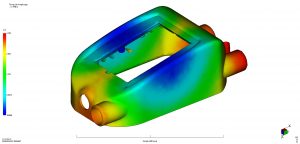

Our Research and Development Department supports you in the conception of your projects, from 2D and 3D drawings and in compliance with your requirements specification. A rheological study would be made before launching your product.

We have a mechanical workshop internally for the conception, the manufacturing and the maintenance of the moulds. Manuthiers realises or outsources, in Europe and in Asia, moulds for every line of business. The moulds are stocked in a secure and firebreak warehouse.

We manage the injection and the bi-injectionprocess, as well as the over-moulding of all kind of insert. We produce parts from 1g to 1 500g, complex or aesthetic parts, in medium or high mass production.

Thanks to the skills of our Industrialisation Department, we can develop several kind of automated process (3 to 6 axis numerical robots, automated assembly straight out of the moulding machine).

Manuthiers has the ISO 9001 certification. Our Metrological Department ensures the parts control with measurement using sensors and camera in an air-conditioned room.

Internally or with our local partners, we can answer your needs in serigraphy, tampography, marking, assembly, bagging, packaging.

Our goods are delivered in France, Europe and Worldwide.