2018 – Investments in moulding machines / Premises adaptation

Acquisition of a 6 Tons Boy XXS moulding machine

Acquisition of a 90 Tons moulding machine with numeric robot

Acquisition of a 130 Tons moulding machine with numeric robot

Late 2018, the production plant is composed of 42 moulding machines from 6 Tons to 485 Tons

Extension of 350 m² on the covered reception / shipping area

2017 – Extension of the injection plant

Integration of 2 new production lines with controled environment

2016 – Investments in moulding machines

Acquisition of a 420 Tons moulding machine with numeric robot

Acquisition of 2 Electric moulding machines of 100 Tons with numeric robot

2014 – Investments in moulding machines

Acquisition of a 320 Tons bi-material moulding machine with rotating plate

2013 – Investments in the mechanical workshop

Acquisition of a wire cutting machine

Acquisition of a laser welding machine

2012 – Investments on moulding machines / Extension of the warehouse

Acquisition of a 320 Tons bi-material moulding machine with rotating plate

Acquisition of 50 Tons Electric moulding machine

Late 2012, the production plant is composed of 32 moulding machines from 6 Tons to 485 Tons

Acquisition of a new machining center 3 axis high speed Victor A110

Warehouse extension : 1 000 m² for the raw material

Extension of more 500 m² on the reception / shipping area

2011 – Investments in moulding machines / peripherals

Acquisition of 2 Electric moulding machines of 100 Tons with numeric robot

Equipment of robots for tandem productions (operations of moulding and overmoulding, or assembly at machine output)

2010 – Investment in moulding machine

Acquisition of a 6 Tons Babyplast moulding machine

2009 – ISO 9001 Certification / Extension of the moulds warehouse

Graduation with the ISO 9001 Certification in November 2009

Extension of more 500 m² warehouse for the largest moulds

2008 – Prototyping

Acquisition of a Cadvision machine

2007 – Investments in moulding machine / CNC / production control

Acquisition of a 485 Tons moulding machines

Acquisition of a new machining center

Acquisition of a Smartscope system with 3 combined measurements (multi-capter optical / video/ sensor)

2006 – Extension of the injection plant

Production plant is doubled

Flow improvement

Development of a zone dedicated to the assembly of subsets

4 500 m² covered production plant

2004 – Legal status change

Change of the legal status from SA to SAS in June 2004

2003 – Iso 9001 Certification / Version 2000 (efficiency)

Graduation with the ISO 9001 Certification

2000 – Iso 9002 Certification (compliance)

The implementation of an Assurance Quality Plan permitted to obtain the ISO 9002 Certification

1999 – Relocation

The increase of the injection plant led the company to build a new location and to move on August the 1st 1999 at Peschadoires. The 2 500 m² covered plant is now more apdated and modern.

1996 – Management

Mr Jean-Marc Pironin becomes CEO of the company

1979 – Legal status change

The business becomes a ‘Société Anonyme’ on July the 1st 1979 and Mr Yves Pironin is CEO

1970 – New markets

The company enters new markets like Agribusiness and Industry, and specialises in overmoulded parts.

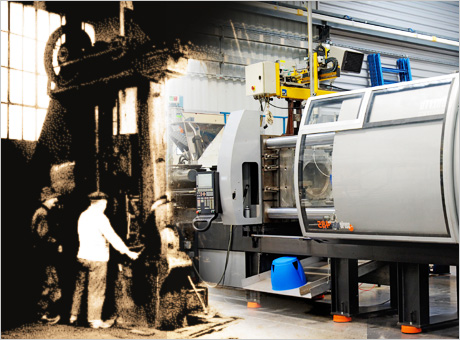

1958 – Innovation in Plastic Injection

The managers gave up with cutlery and innovate in the transformation of plastic materials

1932 – Creation of the company Manuthiers

Creation of the family company in La Monnerie le Montel (close to Thiers) with the manufacturing of cutlery items