An evolving machine fleet

Our mechanical workshop has a constantly evolving machine fleet, allowing us to produce all types of injection molds and ensure their maintenance.

Machining center (DMG – VICTOR). Electroerosion (ONA – CDM – AGIE). Universal milling machines (GAMBIN). Towers (VICTOR). Numerically controlled lathe (SOMAB). Measuring column. Conventional devices.

Around 1,400 molds are stored in secure, temperate buildings that meet firewall standards.

Our specialty, plastic injection

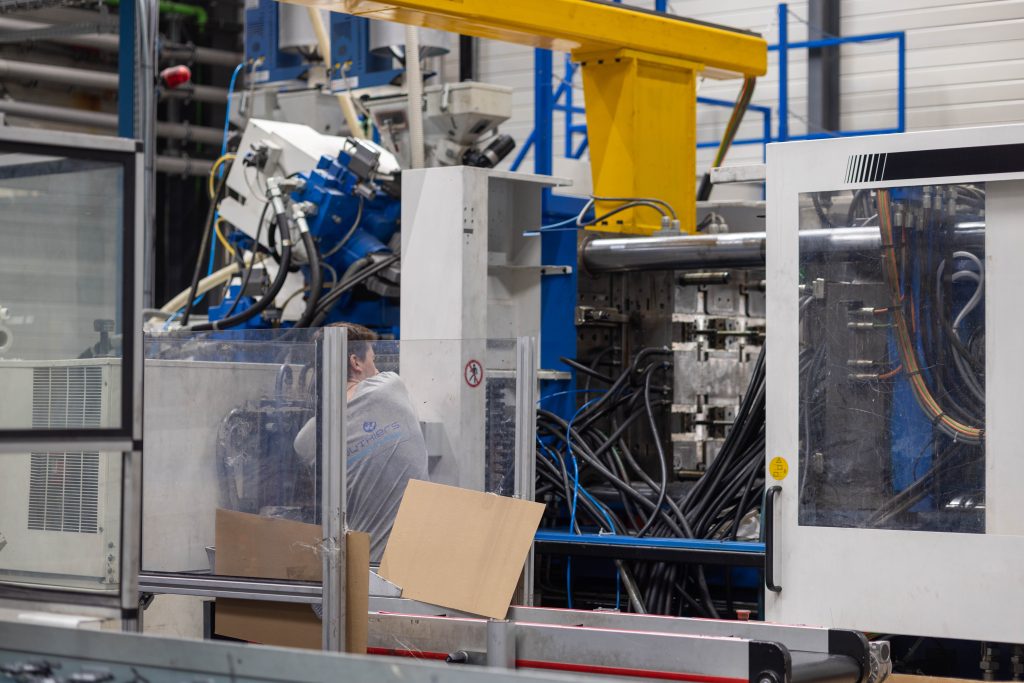

Production

37 presses from 6T to 750 tonnes equipped with various peripherals (robots, conveyor belts, etc.)

Parts from 1g to 1,500g in a range of 300 standard or very technical material references: PE, PP, PA, ABS, POM, PC, SEBS, PETP, PBT, PPS, LNP Faradex, etc.

Flexibility

Our injection production runs 24/7 in three shifts makes it possible to satisfy our customers’ requirements in terms of responsiveness and deadlines (manufacturing constraints, testing and development of tools, presentation of initial samples, etc.) The diversity of the press fleet and the 3×8 activity makes it possible to support projects with low annual production (a few thousand parts), and also to be present on very large volume markets (several million parts).

Discover our creations