Discover our

company

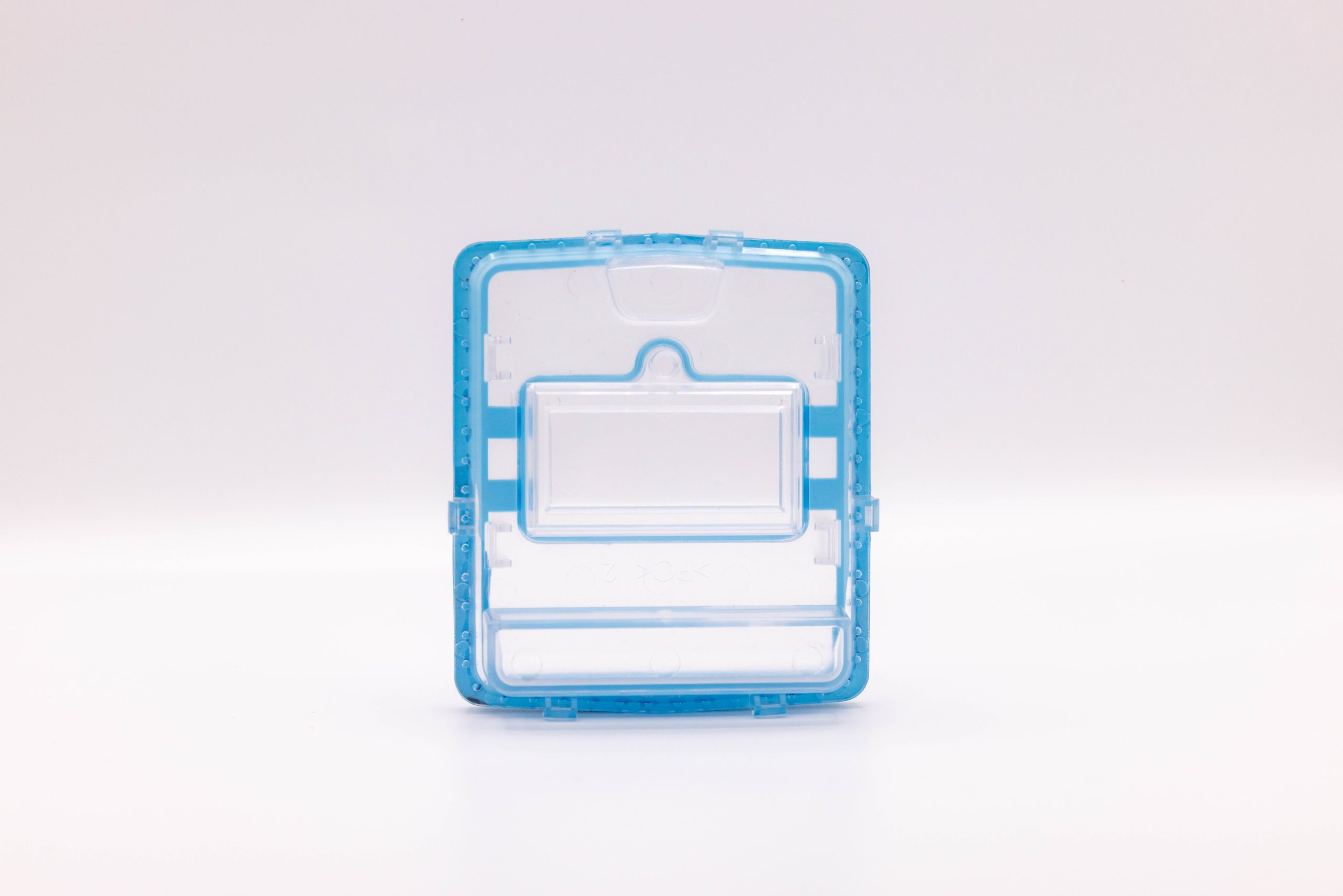

At Manuthiers, we have been cultivating recognized expertise in plastic injection molding for over 65 years.

Located in Auvergne, our family business combines tradition and innovation to meet the specific needs of our customers. Thanks to our high-performance machinery and a team of passionate experts, we design and manufacture high-quality plastic parts for various sectors.

Our commitment? To offer tailor-made, sustainable solutions tailored to technical requirements.

Discover Manuthiers, a human-sized company that places excellence and customer satisfaction at the heart of its priorities.

Our expertise at your service

We are present in many sectors of activity:

Agri-food, Household arts, Building, Hand tools, Transport, Security

goods and people, Equipment for hospitals and communities, Electricity,

Home automation and various industries (hydraulics, aeraulics, pneumatics, etc.….)

Discover our sectors of activity

Our services

Adapting to the demands of new markets, implementing technical and appearance parts, and complying with stringent regulatory standards in sensitive sectors (agri-food, medical, hygiene, etc.) are all factors that are constantly reinforcing our organization to offer services in terms of :

Technical support for your projects

Design and rheology

Advice on thermoplastic materials

Budget alternatives for studies

Injection tooling production

Tooling transfers from France and abroad

Tool storage in secure premises

Automated manufacturing processes

Precision metrology readings

Delivery of finished products

Assembled

Tested

Packed

Technology watch and new emerging

emerging sectors contribute to our

continuous improvement of our

our internal performance,

in line with our ISO 9001 standards.

The production division, based in the Auvergne – Rhône Alpes region, currently has a fleet of 37 presses ranging from 6T to 750 tons.

It incorporates recent investment in new machines, including 320-tonne bi-material presses with digital rotating base. As well as 50- and 100-ton electric presses operating mainly in tandem, either for molding and overmolding requirements, or for parts production with robotized assembly operations at the press exit.

Training also constitutes an essential driver for increasing the skills of each employee and thus enabling them to better manage new tools and materials.

Our gender equality index is 97/100 (50% women, 50% men).

Our goal is efficiency around a partnership, from identifying needs to providing products that meet the requirements of our customers.